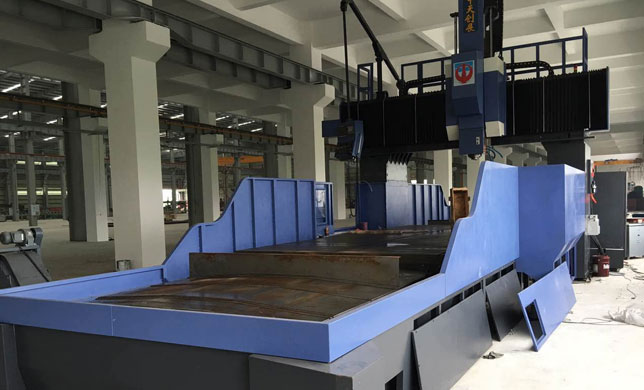

MH electric hoist gantry crane is used together with CD1 and MD1 electric hoist, which can be used in outdoor and indoor workshops

Classification of electric hoist gantry crane:

The shape and structure of electric hoist gantry crane can be divided into: upper and lower flower gantry crane, box gantry crane, flower rack gantry crane, inverted triangle gantry crane, steel tube leg gantry crane.

Technical parameters of electric hoist gantry crane:

Lifting capacity of electric hoist gantry crane: 3T, 5T, 10T, 16T, 20t (non-standard customization is allowed); Lifting height: 6M, 8M, 9M, 12M, 18M, 30m (customizable); Spans are 6.5M, 7.5M, 8.5M, 9.5M, 13.5M, 19.5M, 20.5M, 21.5M, 22.5M, 23.5M and 25.5M (customizable); Running speed of trolley: 20M/MIN, 30M/MIN (can be customized by non-standard design); Working level: A3/M3; Power supply: three-phase AC 380V 50HZ;

Advantages of electric hoist gantry crane:

MH gantry crane is mainly composed of truss, joist, outrigger, etc. The components are connected by axle pairs, which is easy to disassemble and transport; It is equipped with automatic power traveling and lifting equipment, which can realize all-round mechanized action. MH gantry crane is applicable to various fields and mines, open air fixed workshops of enterprises, especially in places with relatively large sand storms. It has the advantages of large lifting capacity, multiple span specifications, stable and safe operation, and wide application.

Working environment of electric hoist gantry crane:

The working environment of MH electric hoist gantry crane is within - 20 ℃ -+40 ℃. It is forbidden to lift molten metal and flammable and explosive articles. It can be made into single-end overhanging cantilever or non-cantilever structure according to customer's requirements. MH electric hoist gantry crane is a general purpose crane, which is mainly used for loading and unloading or grasping materials in outdoor places and indoor warehouses.