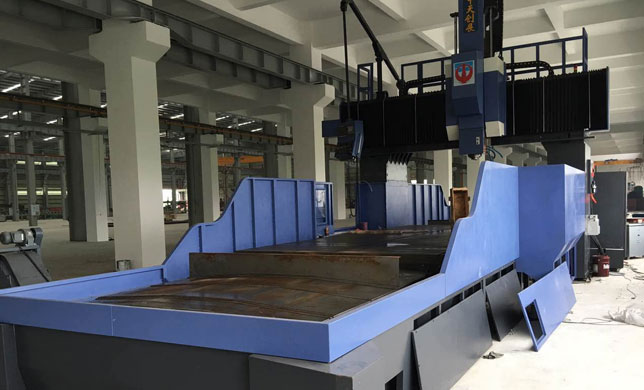

MG type universal gantry crane is suitable for loading, unloading and handling of various materials in open warehouse, cargo (material) yard, railway station and port wharf. Its rated lifting weight is 5~250t, the applicable span is 10~50m, the operating forms are ground control, room control, wireless remote control and the combination of the three.

MG type universal gantry crane structure is mainly composed of metal structure, trolley mechanism (including lifting mechanism and trolley running mechanism), trolley running mechanism and electrical equipment. The lifting mechanism, the trolley running mechanism and the trolley running mechanism are the working mechanism of the crane. According to the actual situation, only single hook can be set, or the tonnage of the main and auxiliary lifting mechanism can be configured according to the user's requirements.

MG universal gantry crane has the following characteristics:

Working level: A5~A7, can adapt to high working frequency and large load.

Operating environment: Temperature -25 ° C to +40 ° C, relative humidity no more than 85%, altitude no more than 2000m.

Truck running speed: The running speed is 10-90m/min, which can be customized by users according to actual needs.

Car running speed: the running speed is 10-45m/min, which can be determined by the user according to the actual needs.

Car lifting speed: lifting speed of 1.5-10m/min, or determined by the user according to the actual needs.

Electrical equipment: Adopt standardized, universal, serialized parts, easy maintenance and replacement, prolong the service life. Adopt frequency conversion control, can automatically adjust the speed of lifting and landing according to the load change.

Change speed

The metal structure part of MG type universal gantry crane includes main beam, upper beam, lower beam, support leg, platform stop bar and control room. The main beam and the main beam, the main beam and the leg, the leg and the lower beam are connected with high strength bolts and become a whole. When the big car running mechanism adopts the separate driving form, the driving device is composed of motor, brake and reducer or the three-in-one driving device is selected. The lifting mechanism is installed on the trolley, which is mainly composed of motor, reducer, brake, reel and hook pulley group. The lifting function of the hook can be achieved as long as the positive and negative rotation of the motor is controlled by winding the wire rope through the drum. The trolley running mechanism is installed on the trolley, which has two forms of centralized drive and separate drive.