Product introduction of three-trolley hoist double-beam crane:

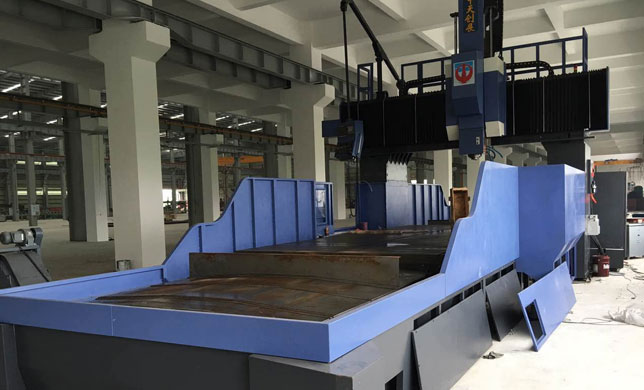

It is generally composed of mechanical, electrical and metal structures. The external image of the double-beam bridge crane is a single-span flat slab bridge supported on two parallel overhead rails.

1. The mechanical part of double-beam bridge crane is divided into three mechanisms, namely lifting mechanism, trolley traveling mechanism and crane traveling mechanism. The lifting mechanism is used to lift articles vertically, and the trolley traveling mechanism is used to move horizontally with load; The crane traveling mechanism is used to move the lifting trolley and goods longitudinally, so as to carry and load and unload goods in three-dimensional space.

2. Metal structure part: composed of bridge and trolley frame.

3. Electrical part: composed of electrical equipment and electrical circuit.

Structural drawing of three-trolley hoist double-beam crane:

1. Bridge: It is composed of two main beams, two end beams, walkways, guardrails and other components. There are two types of structure: box type and truss type.

2. Crane running mechanism: composed of motor, brake, reducer, coupling, transmission shaft, angular bearing box, wheel and other parts.

3. Double-beam bridge crane trolley: composed of trolley frame, lifting mechanism and trolley running mechanism.

4. The lifting mechanism is composed of motor, brake, transmission shaft, coupling, reducer, drum, fixed pulley block, wire rope and other parts. It is divided into single brake and double brake.

5. Double-beam bridge crane cab: the place where the crane operator works. It is equipped with control equipment (linkage console or cam controller), power distribution protection box, signal device and lighting equipment. The crane can only be started after the hatch is closed. This can avoid personal accidents caused by people working on the vehicle or driving before entering the cab.

Components of three-trolley hoist double-beam crane:

The spare parts of double-beam bridge crane mainly include bearings, pulleys, wheels, transmission shafts, wire ropes, brake shoes, buffers and couplings.

1. Hook group: It is a lifting device. Note: there shall be no cracks on the hook surface; Wear at the hook mouth and breakage of pulley rim.

2. Pulley block: divided into movable pulley block and fixed pulley block. Note: whether there are cracks on the surface; Whether the working pulley can rotate flexibly and whether the pulley rim is broken. After the pulley is damaged, users often use brazing (brass water welding) or electric welding to repair it for further use. Due to uneven heating, the pulley is deformed, and the hardness is uneven, which will cause abnormal wear of the wire rope, and the welding quality is not easy, so welding repair is not allowed.

3. Wire rope: attention: broken wire, broken strand, knotting, rust, pitting. Apply lithium grease on the drum for lubrication.

4. Reel group: It is the part used for winding steel wire rope in the lifting mechanism. The gear connection disc drum group is closed transmission with good grouping.

5. Reducer: reduces the high speed of the motor to the required working speed of each mechanism. Commonly used horizontal reducer ZQ and vertical reducer ZSC. Attention: check the oil level; The reducer shall operate smoothly without jumping, impact and violent or intermittent noise, and the sound shall be uniform; Do not loosen at the fastening and connection.

6. Coupling: It is used to connect two rotating shafts arranged on the same axis or basically parallel, transmit torque and compensate a little angle and radial deviation at the same time. Commonly used are CL type gear coupling, CLZ type gear coupling and brake wheel gear coupling. Attention: lubrication, tooth wear.

7. Brake: generally installed on the high-speed shaft of the mechanism to reduce the braking torque. The model of electric hydraulic block brake is YWZ. Attention: lubricate the rotating shaft pin; Observe whether the brake pad is burnt or burnt; Check whether there is oil stain on the brake wheel friction surface.

8. Wheel group: the wheel and angle bearing box are assembled together to form a wheel group. Wheels are divided by wheel rims: double-rim wheels, single-rim wheels; Attention: wear of wheel flange. If the rim is less than 10mm, report it in time and observe it closely.

9. Buffer: used to absorb the energy generated when the crane (or trolley) collides with the stop frame (or bump) or the adjacent cranes on the same span. It is divided into rubber buffer and spring buffer. Note: Check whether it is in good condition.

10. Resistor: An electrical device used to limit the current of a motor. The mechanism starts smoothly to reduce impact.

11. Conductive device: power supply conductive device and trolley conductive device. Safety sliding contact wire collector cable pulley

12. Travel switch: it can be divided into terminal switch (limit switch) and safety switch (protection switch) according to its purpose.

The main technical parameters of the three-trolley hoist double-beam crane are as follows: lifting capacity: 5t, 10t, 16T/3.2t, 20T/5t, 32T/5t, 50T/10t, 75T/20T, 125T/20T, 150T/50T, 160T/50T and other specifications; Span: 10.5m, 13.5m, 16.5m, 19.5m, 22.5m, 25.5m, 28.5m, 31.5m and other specifications. Work level: A5 (for less frequent work, such as general machining and assembly workshops) A6 (for more frequent work, such as metallurgy and foundry workshops) The lifting capacity is expressed in the form of fractions, the numerator is the lifting capacity of the main hook, and the denominator is the lifting capacity of the auxiliary hook.

The work depends on the longitudinal movement along the track direction of the plant, the transverse movement of the trolley and the lifting movement of the hook. QD double-beam crane is applicable to the lifting work of machining and assembly workshops, factories and mines, workshops of enterprises, warehouses, metal structure workshops, machinery maintenance workshops, metallurgy and casting workshops, and various warehouses.