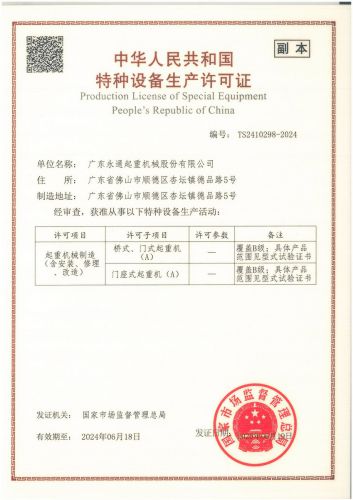

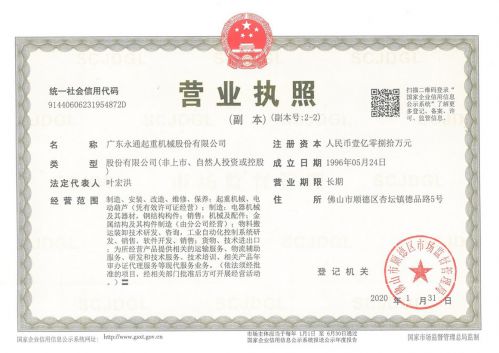

Guangdong Yongtong Crane Machinery Co., Ltd. is a member of China Heavy Machinery Association, a director of bridge crane branch of China Heavy Machinery Industry Association and a director of port machinery branch of China Construction Machinery Association. It is the only strategic partner of German Demag company, a global leading crane enterprise, in Guangdong, China, It has the National A-class crane manufacturing, installation and maintenance qualification. It is the only professional enterprise in the crane industry in Guangdong Province with the ability to produce bridge cranes, gantry cranes, European cranes, automatic cranes, portal cranes and new port lifting and handling machines. At the same time. It is the largest and most complete product variety in the crane industry with the largest production and sales volume in Guangdong Province. In 2010, Yongtong was listed as the key supporting enterprise of Shunde District high-quality enterprise growth project (Longteng plan) by Shunde District People's government. In 2012, it was listed as "key cultivation enterprise of Shunde District" by Shunde District People's government.

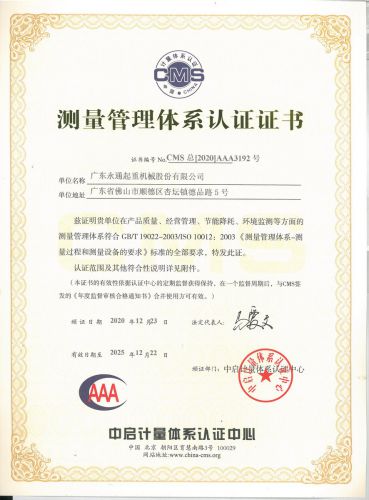

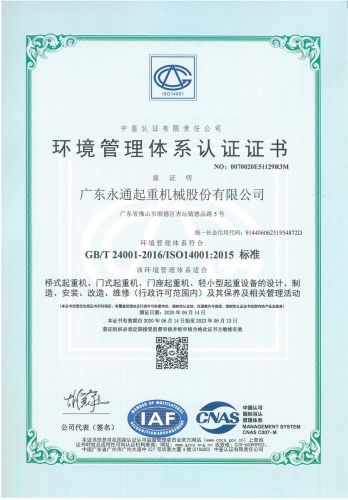

The company has Chencun,Shunde manufacturing base and Xingtan,Shunde manufacturing base, with a total construction area of 130000 square meters and a self use wharf of more than 30000 square meters, which is convenient for the overall assembly and transportation of large cranes. The company has advanced production equipments, accurate and complete detection means, and has high-precision CNC gantry boring and milling machines, floor boring and milling machines, machining centers, CNC lathes, inner circles, outer circle and surface grinders, wire cutting, large gear hobbing machines, large horizontal lathes, CNC plasma underwater cutting machines, CNC plasma pipe cutting machines, robot automatic welding and gantry automatic welding machines.There are nearly 700 sets of advanced and high-precision processing and testing equipments, including advanced main girder forming equipments, main girder reversing equipments, thirteen roll leveling machines, shot blasting machines, complete machine test-bed, as well as various physical and chemical, measurement, flaw detection equipments, laser total station, laser marking instruments and so on, with nearly 500 employees, including more than 130 senior and intermediate professional technicians and managers. The company took the lead in passing the ISO9001 international quality management system certification in the same industry. At present, the company fully implements modern management, fully enables ERP system, PDM system, MES system and OA system for management, as well as 6S management of production site, so that the management level of the enterprise always keeps up with the pace of modern management.

The company has strong technical force and has the qualification of the only R & D center of hoisting and loading machinery in Guangdong Province. The R & D center has a number of senior engineers and professional mechanical, electrical and software engineers, German crane experts, as well as a number of cooperative units, including Logistics Engineering Institute of Wuhan University of technology, Guangdong University of technology, Changjiang Ship Design Institute, Beijing crane research institute and other professional units. At the same time, it has obtained the technical support of Germany Demag Cranes & Components (Shanghai) Co., Ltd. Wuhan University of technology and Guangdong University of technology have many professors, post doctors and doctors all year round, leading and participating in the development of our new products. At present, it has successfully developed European hoist single and double girder crane series, European Open winch crane series, European automatic garbage grab crane series, automatic steel coil crane series and vertical and horizontal automatic oxidation cranes, as well as new port container loading and unloading systems and new lx1000 screw continuous ship unloaders, which have won a number of practical patents and invention patents.The technical level of many products is at the forefront of the country, and some have reached the international advanced level. Nowadays, in the 2025 era of China's manufacturing, Yongtong is developing Internet with cranes, intelligent crane and Internet of things with crane intelligent manufacturing.

Today, Yongtong’s products are widely used in machinery, metallurgy, electric power, electronics, light industry, heavy industry, chemical industry, paper-making, ceramics, building materials, steel processing, railway, water conservancy, port, logistics, automobile, shipbuilding, military industry and other industries. At present, it has gradually entered the fields of new materials, new energy, new power vehicles, rail transit, marine engineering equipments, additive (3D printing), cleaning, robotics, aerospace and other fields, and provided various high-quality crane products for many excellent enterprises and multinational companies. The products sell well all over the country and are exported to more than 60 countries and regions in the world's six continents.

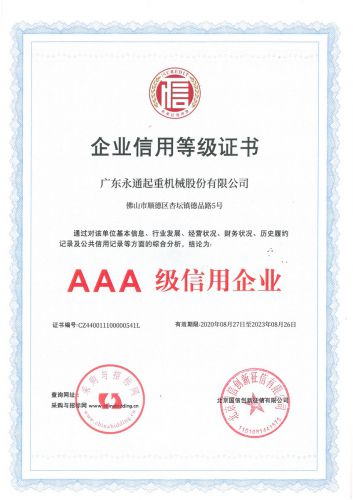

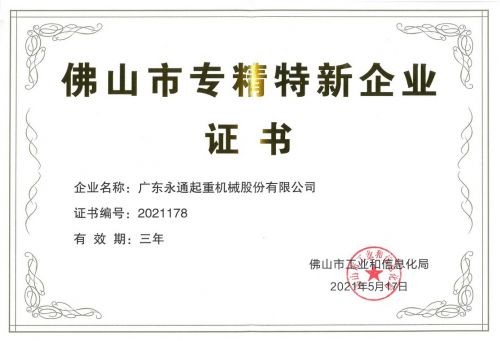

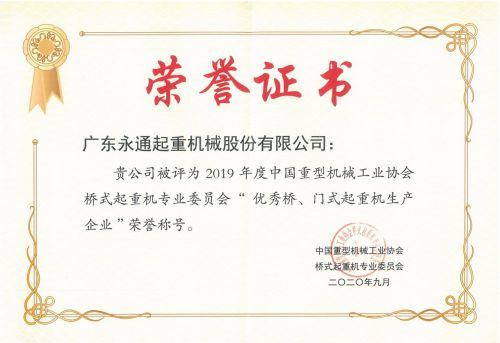

Quality is always the main theme of the enterprise. The excellent product quality has won the market for us and has also been recognized and commended by the quality supervision department and the national quality authority. The company has been successively rated as "Guangdong Famous Brand Product Enterprise", "Guangdong Famous Trademark", "Product Quality Credit AAA+ Enterprise", "China National High-tech Enterprise" by the Guangdong Provincial Bureau of Quality and Technical Supervision, the National Quality Evaluation Center and the Guangdong Provincial Department of Science and Technology. ", "Innovative Industrialization Demonstration Base" and other titles, all kinds of crane products have been awarded quality honorary certificates by the State Bureau of Quality and Technical Supervision for many times. In 2019, Yongtong Heavy Machinery was rated as "Excellent Manufacturing Enterprise of Bridge Gantry Cranes in China" by the Bridge Crane Branch of China Heavy Machinery Association.

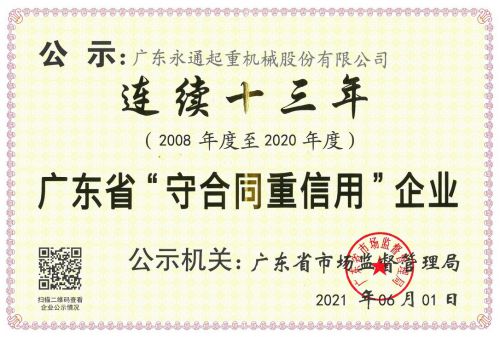

As the user's "quality service enterprise, honest partner" is Yongtong Heavy Machinery's commitment to the majority of users, and it is also the recognition and evaluation of Yongtong Heavy Machinery by our customers. Yongtong Heavy Machinery will maintain this commitment with consistent persistence and enthusiasm. And we are committed to contributing to the industrial upgrading and enterprise development of thousands of outstanding enterprises. We look forward to joining the ranks of partners of more customers, and will always be a "quality service enterprise and honest partner" for our customers.